Food grade hose is an indispensable component in the food and beverage industry, playing a crucial role in maintaining food safety and hygiene throughout the processing chain. These hoses are specifically designed to meet stringent regulatory standards, ensuring that food products are protected from contamination and degradation.

This comprehensive guide delves into the intricacies of food grade hose, exploring their material composition, design, cleaning and maintenance protocols, and proper storage and handling practices. By understanding these aspects, food processors can ensure the longevity and optimal performance of their food grade hoses, safeguarding the integrity and quality of their products.

Industry Applications

Food grade hoses play a crucial role in the food and beverage industry, ensuring the safe and hygienic handling of food products. They are designed to meet stringent regulatory standards, preventing contamination and preserving the quality of food.

Food Processing

- Food grade hoses are used in various food processing operations, including ingredient handling, mixing, and packaging. They ensure the safe transfer of food products without compromising their integrity.

- These hoses are resistant to chemicals and heat, allowing them to withstand the harsh conditions often encountered in food processing environments.

Beverage Production, Food grade hose

- Food grade hoses are essential in beverage production, from fermentation to bottling. They are used to transfer liquids, gases, and ingredients throughout the production process.

- The hoses’ non-porous surface prevents the absorption of flavors or odors, ensuring the preservation of beverage quality.

Dairy Industry

- In the dairy industry, food grade hoses are used to handle milk, cream, and other dairy products. They are designed to withstand the high temperatures and pressures involved in pasteurization and other dairy processing operations.

- These hoses prevent the growth of bacteria and maintain the freshness and quality of dairy products.

Material Composition and Standards: Food Grade Hose

Food grade hoses play a crucial role in ensuring the safety and quality of food products. To fulfill this purpose, they must adhere to strict regulatory standards and be constructed from materials that are inert, non-toxic, and resistant to corrosion and degradation.

The most common materials used in food grade hoses include:

- Stainless Steel:Highly corrosion-resistant, durable, and easy to clean. Meets the standards of the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO).

- Ethylene Propylene Diene Monomer (EPDM):A synthetic rubber that is resistant to heat, ozone, and chemicals. Complies with the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) regulations.

- Polytetrafluoroethylene (PTFE):A fluoropolymer known for its exceptional chemical inertness and high-temperature resistance. Meets the FDA and ISO standards.

In addition to material composition, food grade hoses must also comply with various regulatory standards and certifications. These standards ensure that the hoses are manufactured and tested to meet the highest levels of safety and quality.

- FDA:The FDA regulates the materials used in food contact applications in the United States.

- ISO:The ISO develops international standards for food safety and quality management systems.

- NSF International:An independent organization that certifies food grade hoses and other food-related products.

By meeting these regulatory requirements and using approved materials, food grade hoses ensure the safety and integrity of food products throughout the manufacturing, processing, and distribution processes.

Design and Construction

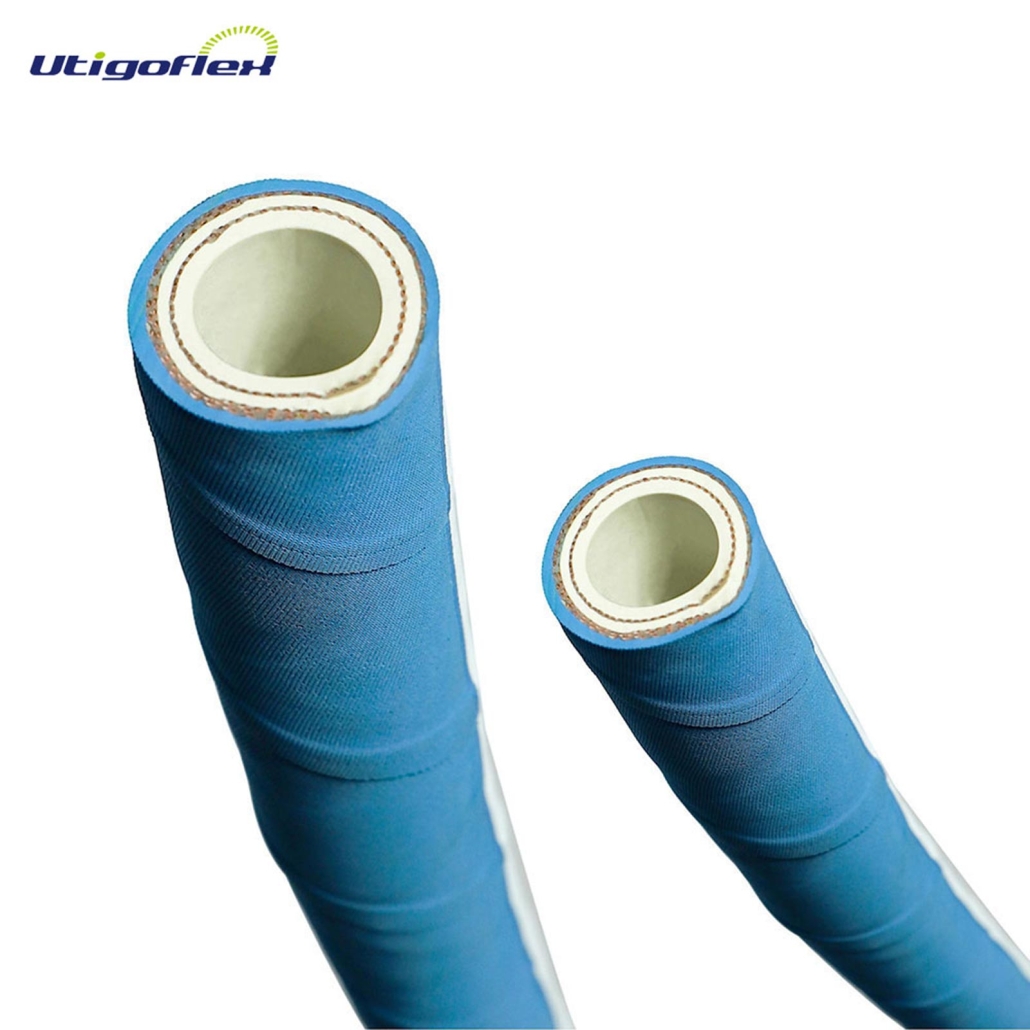

Food grade hoses are meticulously designed and constructed to ensure their suitability for use in the food industry. These hoses exhibit exceptional flexibility, allowing them to be easily maneuvered and installed in complex piping systems. Their robust construction guarantees durability, withstanding the rigors of industrial food processing environments.

The design of food grade hoses prioritizes temperature resistance, enabling them to handle a wide range of temperatures encountered in food processing applications. This versatility allows them to safely convey fluids ranging from cold beverages to hot sanitizing solutions.

Construction Techniques

Food grade hoses are constructed using advanced techniques to ensure they meet stringent food safety standards. These techniques include:

- Smooth Inner Surface:The interior of food grade hoses is meticulously crafted to be smooth and free of imperfections, minimizing the risk of bacteria or debris accumulation.

- Non-Toxic Materials:The materials used in food grade hoses are carefully selected to ensure they are non-toxic and do not leach harmful substances into the food products.

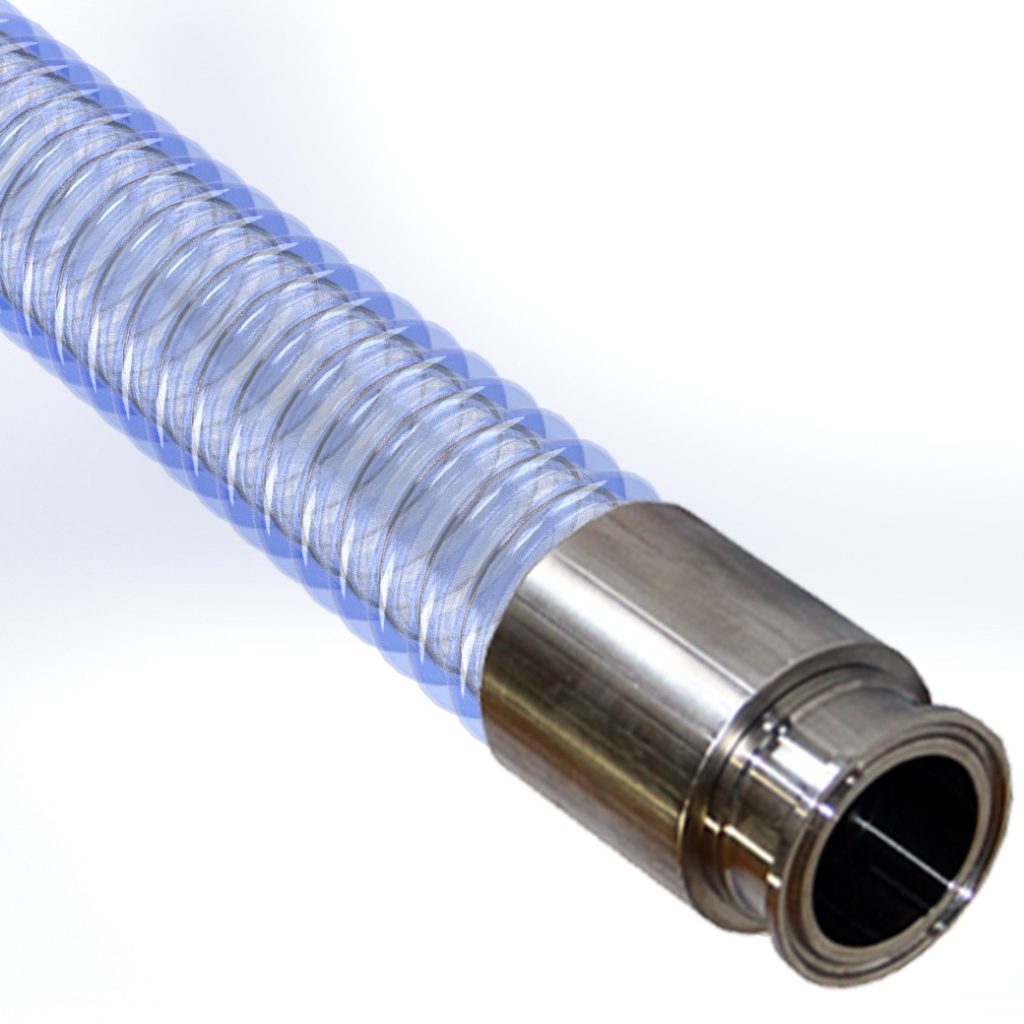

- Durable Reinforcement:Food grade hoses are reinforced with high-strength materials, such as stainless steel or synthetic fibers, to withstand pressure and prevent kinking or rupture.

- Leak-Proof Fittings:The fittings used to connect food grade hoses are designed to be leak-proof, ensuring a secure and sanitary connection.

Cleaning and Maintenance

Proper cleaning and maintenance are essential to ensure the safety and longevity of food grade hoses. Regular cleaning removes contaminants and bacteria that can accumulate over time, preventing the risk of food contamination.

Cleaning Methods

The most effective cleaning method for food grade hoses depends on the specific application and type of hose. Common cleaning methods include:

- Chemical Cleaning:Using food-grade detergents or sanitizing solutions to remove organic matter and bacteria.

- Steam Cleaning:Exposing the hose to high-temperature steam to kill bacteria and remove stubborn residues.

- Mechanical Cleaning:Using brushes or other mechanical devices to physically remove debris from the hose surface.

Detergent Selection

Food-grade detergents specifically designed for cleaning food contact surfaces should be used. These detergents are non-toxic and meet industry standards for food safety. Avoid using harsh chemicals or abrasive cleaners that can damage the hose material.

Inspection and Monitoring

Regular inspection of food grade hoses is crucial to identify any damage or wear that could compromise food safety. Check for cracks, leaks, or other defects that may allow contaminants to enter the hose. Keep a record of inspections and cleaning procedures for traceability and compliance purposes.

Storage and Handling

Proper storage and handling of food grade hoses are essential to maintain their longevity, performance, and sanitary integrity. Neglecting these aspects can lead to premature deterioration, contamination, and compromised food safety.

Proper Storage

- Store hoses in a cool, dry, and well-ventilated area away from direct sunlight and extreme temperatures.

- Keep hoses coiled loosely to prevent kinking and damage.

- Suspend hoses off the ground or hang them on racks to allow for proper airflow and prevent moisture accumulation.

- Avoid storing hoses near sharp objects or chemicals that could puncture or damage them.

Proper Handling

- Handle hoses carefully, avoiding excessive bending or twisting that could damage the inner lining.

- Do not drag hoses across rough surfaces, as this can cause abrasion and wear.

- Use proper fittings and connections to ensure secure attachment and prevent leaks.

- Regularly inspect hoses for any signs of damage or wear, and replace them promptly if necessary.

Essential FAQs

What are the common materials used in food grade hoses?

Food grade hoses are typically made from materials such as EPDM, nitrile, and polyurethane, which are FDA-approved and meet regulatory standards for food contact.

How often should food grade hoses be cleaned and inspected?

Regular cleaning and inspection of food grade hoses are crucial to maintain food safety. The frequency of cleaning depends on the specific application and usage, but it is generally recommended to clean hoses daily or as per the manufacturer’s guidelines.

What are the potential risks associated with improper storage or handling of food grade hoses?

Improper storage or handling of food grade hoses can lead to contamination, damage, or premature failure. It is important to store hoses in a clean, dry place, away from direct sunlight and extreme temperatures.