How much bacteriostatic water to mix with 3mg of semaglutide? This crucial question arises when preparing this medication for administration. Proper mixing is essential for maintaining semaglutide’s efficacy and safety. Understanding the precise volume of bacteriostatic water required, alongside the steps involved in the mixing process, is vital for ensuring optimal results.

This comprehensive guide delves into the specifics of mixing semaglutide with bacteriostatic water. We’ll explore the characteristics of bacteriostatic water, the properties of semaglutide, and the crucial mixing ratios and procedures. We’ll also address potential issues and considerations, emphasizing the importance of aseptic technique and safe handling practices.

Defining Bacteriostatic Water

Marpasa ni ro di sima, onom ni sima, taringot tu aek ni napegon tu panahanan ni bakteri. Understanding this water is crucial in pharmaceutical preparations, especially when handling delicate substances like semaglutide.Bacteriostatic water plays a vital role in preventing bacterial contamination during the mixing process. Its unique properties are essential to maintain the integrity and efficacy of the medication.

Chemical Composition and Properties

Bacteriostatic water, unlike regular purified water, contains added substances that inhibit the growth of microorganisms. These substances, typically antimicrobial preservatives, are carefully selected and regulated to ensure safety and efficacy. The exact chemical composition varies depending on the specific type of bacteriostatic water.

Mechanisms of Bacterial Inhibition

Bacteriostatic water achieves its antimicrobial effect through various mechanisms. Some common methods involve disrupting the cell wall structure of bacteria, inhibiting metabolic processes, or interfering with DNA replication. The specific mechanism depends on the chemical composition of the preservative.

Types of Bacteriostatic Water and Applications

Several types of bacteriostatic water are available, each with its specific application in the pharmaceutical industry. These may include:

- Water for Injection (WFI) with Preservative: Used extensively in parenteral preparations, where sterility is paramount. The preservative ensures the sterility of the final product, especially in solutions that may be stored for extended periods.

- Water for Irrigation: Used in procedures that involve flushing or irrigating body cavities. Preservatives are chosen for compatibility with the specific tissue or area being treated.

- Water for External Use: This water is formulated to maintain sterility and prevent bacterial growth in topical applications. The preservatives used are carefully chosen for safety and compatibility with the skin.

Comparison with Other Water Types

Compared to other types of water used in pharmaceutical preparations, such as purified water, bacteriostatic water has an added antimicrobial agent. This makes it essential for situations where the risk of microbial contamination is high. Purified water, while safe, does not contain the same antimicrobial properties. Sterile water for injection, while sterile, does not always have the bacteriostatic properties required for long-term storage of solutions.

Properties of Bacteriostatic Water

| Property | Description | Significance in Drug Mixing |

|---|---|---|

| Antimicrobial Activity | Contains added preservatives that inhibit bacterial growth. | Crucial for maintaining the sterility and efficacy of the drug preparation. |

| Chemical Stability | Preservatives are chosen for their stability under various storage conditions. | Ensures the preservative remains effective throughout the shelf life of the drug product. |

| Compatibility with Drugs | Preservatives are carefully selected to avoid interactions with the drug. | Prevents potential chemical reactions or degradation of the drug during mixing. |

| Sterility | The water is typically sterilized prior to addition of preservatives. | Maintains the sterile environment crucial for drug mixing and ensures patient safety. |

| pH | Maintained within a specific range to ensure compatibility with the drug. | Prevents the drug from degrading or becoming ineffective due to pH changes. |

Understanding Semaglutide: How Much Bacteriostatic Water To Mix With 3mg Of Semaglutide

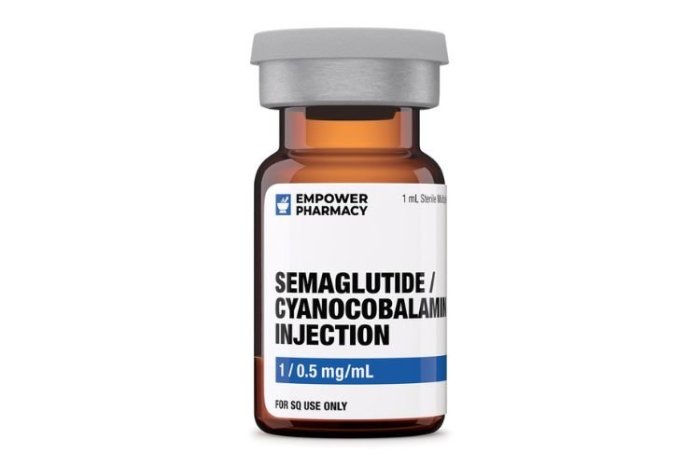

Semaglutide, a glucagon-like peptide-1 (GLP-1) receptor agonist, is a medication used to manage type 2 diabetes and promote weight loss. Its unique chemical structure and properties contribute to its effectiveness and, importantly, its potential stability challenges in various solutions. Understanding these aspects is crucial for safe and effective preparation and administration.

Chemical Structure and Properties

Semaglutide’s structure is a key factor in its function and stability. It is a modified GLP-1 analog, meaning it’s a similar but altered version of the naturally occurring hormone. This modification enhances its stability in the body and allows for its use as a medication. The specific modifications affect the molecule’s interaction with the GLP-1 receptor, leading to its intended effects.

Crucially, its lipophilic nature, and the presence of specific functional groups, can influence its solubility and stability in different solutions.

Intended Use and Mechanism of Action

Semaglutide is primarily used to improve glycemic control in type 2 diabetes. It works by mimicking the action of GLP-1, a naturally occurring hormone that regulates blood sugar levels. By binding to and activating GLP-1 receptors, semaglutide stimulates insulin secretion, suppresses glucagon release, and slows gastric emptying. These actions contribute to lower blood sugar levels and reduced appetite, which are beneficial in managing diabetes and promoting weight loss.

Stability Concerns in Various Solutions

Semaglutide’s stability in different solutions is a significant concern. Its protein nature makes it susceptible to degradation by various factors, such as temperature fluctuations, pH changes, and presence of certain substances. Storage conditions significantly impact the drug’s potency and efficacy. The presence of incompatible compounds can also accelerate its breakdown, affecting its effectiveness.

Importance of Maintaining Correct pH and Concentration

Maintaining the correct pH and concentration of the solution containing semaglutide is vital for its stability. Deviations from the prescribed parameters can lead to significant degradation. This degradation can reduce the drug’s potency and potentially lead to adverse effects. The manufacturer’s recommended pH range and concentration limits must be carefully followed.

Potential Interactions with Bacteriostatic Water

Bacteriostatic water, while crucial for preventing microbial growth, can potentially interact with semaglutide. The presence of preservatives or other components in the bacteriostatic water may influence semaglutide’s stability. This interaction may result in altered drug activity or potentially even cause precipitation. Therefore, careful consideration and compatibility testing between the two are crucial for safe and effective preparation.

Mixing Ratios and Procedures

Marhite marhite, dibahen ma proses marsirang ni aek bakteriostatik dohot semaglutide 3mg. Penting jala ringgas dipatimbo proses on, asa dapot hasil na denggan jala aman. Sai tongtong dipaingat ma teknik aseptik, asa unang masuk bakteri na berbahaya.

Mixing Process Overview

The mixing process involves carefully combining the prescribed amount of semaglutide with the appropriate volume of bacteriostatic water. Precise measurements are crucial to ensure the correct dosage and prevent potential complications. The process must be conducted in a sterile environment to maintain the integrity of the solution and prevent contamination.

Step-by-Step Procedure

To ensure accuracy and safety, a step-by-step procedure is presented below. This method is vital for preparing a safe and effective solution.

- Preparation: Ensure all materials are sterilized and ready. This includes the sterile vials or syringes, bacteriostatic water, and semaglutide. Prepare a clean, sterile workspace.

- Measurement: Accurately measure the prescribed 3mg of semaglutide using a sterile, calibrated scale. Then, measure the appropriate volume of bacteriostatic water, as per the manufacturer’s instructions or doctor’s prescription.

- Vial/Syringe Selection: Select a sterile vial or syringe of suitable size to accommodate the mixed solution. Verify that the container is appropriate for the final volume.

- Aseptic Technique: Maintain aseptic technique throughout the entire process. This means working in a clean environment and using sterile equipment to avoid contamination. Use gloves and a mask, if necessary.

- Mixing: Gently swirl the vial or syringe to dissolve the semaglutide in the bacteriostatic water. Avoid vigorous shaking, as this can introduce bubbles or cause precipitation. Observe the dissolution process; it should dissolve completely without residue.

- Inspection: Inspect the solution for any signs of precipitation, discoloration, or other abnormalities. If anything is amiss, discard the solution and repeat the process using a new batch of materials.

- Storage: Store the prepared solution in a refrigerator, properly labeled with the date, time, and content. Follow manufacturer’s instructions on appropriate storage duration.

Mixing Methods Comparison

Different mixing methods can affect the outcome of the solution. A suitable method is critical for proper dissolution and preventing issues.

| Mixing Method | Description | Impact on Solution |

|---|---|---|

| Gentle Swirling | Slowly rotating the vial or syringe to mix. | Generally effective for dissolving semaglutide; minimizes the formation of bubbles and potential precipitation. |

| Vortexing | Using a vortex mixer to agitate the solution rapidly. | Can effectively dissolve semaglutide but may introduce bubbles or cause precipitation if done vigorously. |

Importance of Aseptic Technique

Aseptic technique is critical to prevent contamination of the solution. Microorganisms can cause significant issues and even lead to health problems. It is essential to maintain a clean workspace and use sterile equipment throughout the mixing process.

Potential Issues and Considerations

Marhite ma ias di bagas ni proses ni campuran, di naeng dipatuduhon siat-siat ni tantangan na dob jala parmingguhon naeng dijaga. Di naeng dibahen pe parmingguhon, naeng dijaga pe asa unang dipatiris naeng ni hona ni masalah na dob jala naeng dijaga pe asa unang dipaida proses ni campuran.Di naeng dibahen pe campuran ni semaglutide dohot aic ni bacteriostatic, naeng dijaga pe asa unang hona dampak ni proses ni campuran i tu efektifitas dohot keamanan ni semaglutide.

Di naeng dibahen pe parmingguhon, naeng dijaga pe asa unang hona dampak ni proses ni campuran i tu efektifitas dohot keamanan ni semaglutide.

Potential Challenges During Mixing, How much bacteriostatic water to mix with 3mg of semaglutide

Masalah na boi masa di bagasan proses ni campuran i ima, naeng dijaga pe asa unang masa salah ni ukuran. Naeng dijaga pe asa unang salah ni ukuran ni air ni bacteriostatic dohot semaglutide. Naeng dijaga pe asa unang salah ni waktu ni campuran. Di naeng dijaga pe asa unang masa kesalahan ni suhu. Suhu na salah boi mangaruh tu stabilitas ni larutan i.

Impact on Efficacy and Safety

Jala, naeng dijaga pe asa unang dipatirisi dampak ni proses ni campuran na salah tu efektifitas dohot keamanan ni semaglutide. Salah ni ukuran, salah ni waktu, dohot suhu na salah boi mangaruh tu kualitas ni larutan. Jala, naeng dijaga pe asa unang masa masalah na dob jala naeng dijaga pe asa unang masa masalah na dob jala naeng dijaga pe asa unang masa masalah na dob.

Critical Factors for Stable Solution

Faktor na penting naeng dijaga ima: akurasi ni ukuran, waktu ni campuran na tepat, dohot suhu na sesuai. Di naeng dijaga pe asa unang masa masalah na dob jala naeng dijaga pe asa unang masa masalah na dob. Naeng dijaga pe asa unang salah ni ukuran ni semaglutide dohot air ni bacteriostatic. Jala, naeng dijaga pe asa unang salah ni waktu ni campuran.

Jala, naeng dijaga pe asa unang salah ni suhu. Suhu na salah boi mangaruh tu stabilitas ni larutan.

Safety Precautions

Naeng dijaga pe asa unang masa kecelakaan di proses ni campuran. Jala, naeng dijaga pe asa unang masa masalah na dob jala naeng dijaga pe asa unang masa masalah na dob. Naeng dijaga pe asa unang salah ni proses ni campuran. Naeng dijaga pe asa unang salah ni ukuran, waktu, dohot suhu. Naeng dijaga pe asa unang salah ni proses ni campuran.

Di naeng dijaga pe asa unang masa kesalahan na dob jala naeng dijaga pe asa unang masa kesalahan na dob. Ingat, pakailah alat pelindung diri (APD) seperti sarung tangan dan masker.

Common Mistakes to Avoid

Salah satu kesalahan na boi masa ima, salah ni ukuran. Salah ni waktu, dohot suhu na salah boi mangaruh tu stabilitas ni larutan.

Naeng dijaga pe asa unang salah ni ukuran ni semaglutide dohot air ni bacteriostatic. Jala, naeng dijaga pe asa unang salah ni waktu ni campuran. Jala, naeng dijaga pe asa unang salah ni suhu. Suhu na salah boi mangaruh tu stabilitas ni larutan. Naeng dijaga pe asa unang masa kesalahan ni proses ni campuran.

Storage and Handling

Maintaining the integrity and efficacy of the prepared semaglutide solution is crucial. Proper storage and handling practices are essential to prevent degradation and ensure the solution remains fit for its intended use. This section details the optimal conditions for storage, recommended handling procedures, and the expected shelf life of the prepared solution. Following these guidelines will help ensure the solution maintains its potency and effectiveness.

Optimal Storage Conditions

The prepared semaglutide solution requires specific environmental conditions to prevent degradation. These conditions influence the stability and efficacy of the active ingredient. Maintaining the right temperature and avoiding light exposure are critical.

- Temperature Control: Store the solution in a refrigerator (2-8°C) to maintain optimal stability. Exposure to higher temperatures can lead to accelerated degradation of the active ingredient. For example, leaving the solution in a warm car or on a countertop can cause the semaglutide to break down, reducing its potency.

- Light Protection: Store the solution in an opaque container to prevent degradation from light exposure. Light can initiate chemical reactions that affect the semaglutide’s structure and activity. For instance, prolonged exposure to sunlight can diminish the effectiveness of the drug. Using amber or opaque containers is advisable.

- Proper Container: Use a clean, airtight container to prevent contamination and evaporation. This ensures the solution remains sealed and prevents any unwanted substances from entering the mix. For instance, using a tightly sealed vial or bottle helps to maintain the integrity of the solution.

Recommended Handling Procedures

Adhering to specific handling procedures helps preserve the integrity of the prepared solution. These procedures aim to minimize the risk of contamination and maintain the potency of the solution.

- Aseptic Technique: Handle the solution using aseptic techniques to prevent microbial contamination. This includes using sterile equipment and maintaining a clean work environment to avoid introducing microorganisms into the solution. This will prevent the solution from spoiling and losing potency.

- Avoid Repeated Exposure: Minimize repeated exposure to the solution to avoid unnecessary manipulation. Every time the solution is handled, there’s a potential for contamination. Thus, handling it only when necessary is important.

- Proper Mixing: Ensure the solution is thoroughly mixed to ensure even distribution of the active ingredient. This ensures the desired concentration is maintained throughout the solution. For example, proper shaking of the solution before each use is recommended.

Shelf Life

The shelf life of the prepared semaglutide solution is dependent on adherence to the storage conditions. Deviations from the recommended guidelines can significantly shorten the usable lifespan. For example, improper storage or handling practices will reduce the shelf life.

Shelf life is typically around 28 days, provided the solution is stored under proper refrigeration conditions (2-8°C).

Summary of Optimal Storage Conditions

| Parameter | Optimal Condition |

|---|---|

| Temperature | 2-8°C (Refrigerator) |

| Light Exposure | Avoid direct light; use opaque container |

| Container | Clean, airtight container |

Potential Degradation Pathways

Several pathways can lead to the degradation of the semaglutide solution. Understanding these pathways helps in implementing preventive measures.

- Hydrolysis: The semaglutide molecule may undergo hydrolysis, which involves the reaction with water. This reaction can break down the molecule, reducing its potency. This reaction is temperature-dependent, with higher temperatures increasing the rate of hydrolysis.

- Oxidation: Exposure to oxygen can lead to oxidation, which can alter the chemical structure of the semaglutide molecule. This process can also reduce the efficacy of the solution. This is why it is important to store the solution in an airtight container to limit exposure to oxygen.

- Microbial Contamination: Contamination with microorganisms can lead to the growth of bacteria or fungi, which can further degrade the semaglutide molecule and produce toxins that can harm the recipient. Maintaining a sterile environment during handling is critical.

Illustrative Examples

Marga ni siam, dipaima be dibahen ni angka contoh-contoh ni angka perbandingan ni aek ni bacteriostatic dohot semaglutide 3mg. Di bagasan angka contoh on, banuaon do angka hasil ni angka perbandingan siparluhon dohot angka perhatian ni angka keselamatan.Marhitei angka contoh-contoh on, pintor ma hita mangarusi angka perbandingan siparluhon jala angka perhatian ni angka keselamatan di bagasan proses ni pencampuran.

Mixing Ratio Example 1

Di bagasan contoh parjolo on, diparluhon 1 ml aek ni bacteriostatic laho manggombarhon semaglutide 3 mg. Hasil na diida ima, angka semaglutide on patut diadopi secara aman. Namun, penting do dipaima be, bahenon angka pengukuran na akurat laho pastika hasil na aman jala na efektif.

Mixing Ratio Example 2

Molo diparluhon 0.5 ml aek ni bacteriostatic, mungkin adong do angka tantangan. Angka semaglutide boi do tarjamur jala dang efektif, jala mungkin boi do adong angka resiko ni keselamatan. Penting do dipaima be bahenon angka pengukuran na akurat, jala na tepat.

Comparison Table of Mixing Ratios

| Volume Aek Bacteriostatic (ml) | Hasil | Perhatian ni Keselamatan |

|---|---|---|

| 1 ml | Aman, efektif | Tidak ada resiko signifikan |

| 0.5 ml | Mungkin kurang efektif, resiko tarjamur | Perlu diperhatikan, pengukuran tepat penting |

| 2 ml | Aman, efektif | Tidak ada resiko signifikan |

Penting do dipaima be bahenon angka pengukuran na akurat, jala na tepat. Angka angka pengukuran na salah boi mangarusi angka hasil na kurang efektif jala boi mangarusi angka resiko ni keselamatan.

Visual Representation of Mixing Process

Ima, itakkuhon ma proses ni pencampuran i. Dipaima ma angka alat na bersih jala na steril. Parjolo, taruhon ma semaglutide i di bagasan vial na bersih. Dung i, tambahkan ma aek ni bacteriostatic i di bagasan vial i, jala aduk ma secara perlahan jala sempurna. Penting do dipaima be, angka alat ni diparluhon i dijaga na bersih jala na steril.

Itakkuhon ma angka pengukuran na akurat. Pastikan do angka semaglutide i diadopi secara sempurna.

Last Point

In conclusion, accurately mixing 3mg of semaglutide with the correct volume of bacteriostatic water is critical for successful and safe administration. Adhering to the detailed procedures, safety precautions, and storage guidelines Artikeld in this guide will help ensure optimal results. Remember, precision and meticulousness are key to achieving a stable and effective solution.

General Inquiries

What are the potential side effects of using the incorrect mixing ratio?

Using the incorrect mixing ratio can lead to altered drug absorption, reduced efficacy, and potentially adverse effects. It’s crucial to follow the precise mixing instructions to avoid these risks.

How long can the prepared solution be stored?

The shelf life of the prepared solution will vary depending on storage conditions. Always refer to the specific guidelines provided in the semaglutide package insert or from a qualified healthcare professional.

What kind of equipment is necessary for mixing?

Essential equipment includes sterile containers, aseptic technique, and precise measuring devices. Specific instructions may vary; always consult the manufacturer’s instructions.

What are the signs of a poorly mixed solution?

Signs of a poorly mixed solution might include precipitation, unusual color changes, or an uneven consistency. If any of these are observed, discard the solution and prepare a fresh batch.