How to adapt 3 pt lawn rake to my bucket – How to adapt 3 pt lawn rake to your bucket? This guide unveils the secrets to transforming your standard lawn rake into a powerful, versatile tool for your bucket. Discover the straightforward process, maximizing efficiency and expanding your outdoor work capabilities. Learn about suitable rake and bucket combinations, essential planning and design steps, and the practical implementation of this modification.

Enhance your yard work with a custom-made solution, meticulously detailed in this comprehensive guide.

Transforming your 3-point lawn rake into a bucket-mounted tool opens up a world of possibilities. Imagine effortlessly collecting leaves, debris, or even small garden cuttings directly into your bucket. This adaptation is ideal for larger yards, simplifying the cleanup process and boosting productivity.

Introduction to Adapting a 3-Point Lawn Rake to a Bucket

Adapting a 3-point lawn rake to a bucket can significantly enhance its utility for various yard tasks. This modification allows for efficient collection and transport of leaves, grass clippings, or other debris, transforming a simple rake into a more versatile tool. The process is relatively straightforward and can be tailored to suit the specific needs and available resources of the user.This adaptation offers numerous benefits.

It boosts efficiency by enabling the collection of debris directly into a container, reducing the time spent on manual cleanup. This is particularly helpful for large areas or when dealing with a significant volume of yard waste. The adaptation also allows for more controlled transport, preventing debris from scattering or getting lost.

Necessary Tools and Materials

Proper preparation is crucial for a successful adaptation. The essential tools include a sturdy bucket, appropriate fasteners (bolts, screws, or welding materials), a measuring tape, and various hand tools like a drill or wrench, depending on the bucket and rake type. Securing the rake to the bucket effectively is vital for preventing slippage and ensuring the longevity of the modified tool.

Types of Buckets

A range of buckets can be used for this adaptation. Common choices include metal or plastic buckets, with metal being preferable for heavy-duty applications and plastic for lighter-weight options. The choice of material should be aligned with the intended usage. Consider the size of the bucket; larger buckets are better suited for collecting large quantities of debris.

Also, ensure the bucket has a secure lip or rim to prevent the rake from slipping off.

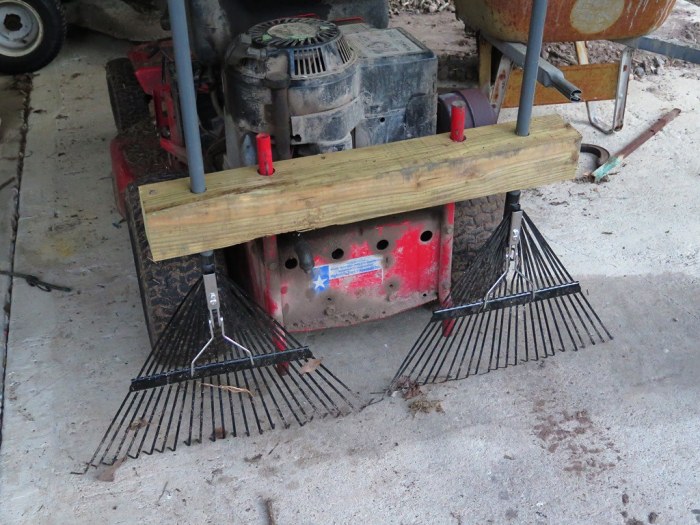

Diagram of the Rake and Bucket Arrangement

The following diagram illustrates a simple arrangement of the 3-point lawn rake and bucket. The rake tines are securely attached to the bucket’s side using appropriate fasteners, such as bolts or screws, ensuring the rake is positioned to efficiently collect debris. The rake is placed in a way that the tines will contact the ground and push the debris into the bucket.

The tines of the rake should extend slightly beyond the edge of the bucket to maximize the debris collection area.

Note

A diagram depicting the rake attached to the bucket would be a better representation here. This description aims to provide clarity in the absence of the image.*

Identifying Suitable Rake and Bucket Combinations

Picking the right 3-point rake and bucket is crucial for a successful adaptation. Mismatched dimensions or material incompatibility can lead to a poorly functioning, potentially dangerous setup. Careful consideration of both the rake’s design and the bucket’s properties is essential for a safe and effective attachment.

Compatible Rake Models

Choosing the right rake model is paramount. Look for rakes designed for heavy-duty use and featuring robust construction. Rakes with a wide tines’ spacing and sturdy construction are ideal. This structural strength will be vital to withstand the stresses of use. Avoid flimsy rakes prone to bending or breaking under load.

Crucially, the rake’s tines must be positioned to allow for secure and stable mounting to the bucket.

Essential Rake Features

A suitable rake will have key features that facilitate the attachment process. The rake’s mounting points should be precisely engineered for a secure connection to the bucket. These mounting points are essential for maintaining the rake’s structural integrity. The rake should also have a design that allows for proper adjustment and alignment. This adjustment allows for precise control over the rake’s position relative to the bucket, critical for efficient operation.

Furthermore, the rake should have an overall design that aligns with the structural integrity and load-bearing capacity of the bucket.

Dimensional Compatibility

Matching the rake’s dimensions to the bucket’s dimensions is vital. The rake’s width, height, and overall shape should be carefully measured and compared to the bucket’s specifications. Rake’s mounting points and the bucket’s attachment areas must align to ensure secure connection. An oversized or undersized rake will impede operation. Precise measurement of both the rake and bucket is critical for compatibility.

Thorough examination of available models is needed.

Bucket Material Considerations

The material of the bucket significantly impacts its strength and durability. Steel buckets are generally robust and can withstand heavy loads. However, they can be more prone to rust and corrosion, requiring regular maintenance. Aluminum buckets, while lighter, might not possess the same load-bearing capacity as steel. Their lighter weight makes them easier to maneuver, though.

The choice between steel and aluminum depends on the intended application.

| Material | Pros | Cons |

|---|---|---|

| Steel | High load capacity, durable | Heavier, prone to rust |

| Aluminum | Lightweight, easy to maneuver | Lower load capacity, potential for damage |

Planning and Design of the Adaptation: How To Adapt 3 Pt Lawn Rake To My Bucket

Getting the rake and bucket setup right is crucial for efficient operation. A well-planned adaptation ensures a robust and effective attachment, maximizing the rake’s functionality within the bucket’s framework. A clear design, accurate measurements, and appropriate attachment points are vital for successful integration.

Sketching the Design

Visualizing the adaptation before any physical modifications is essential. A preliminary sketch, even a simple one, helps in conceptualizing the arrangement of the rake within the bucket. This sketch should depict the rake’s position relative to the bucket’s structure, including the attachment points. Consider angles, leverage, and potential stress points. A well-executed sketch provides a roadmap for the physical adaptation process.

Measuring and Marking for Modification

Accurate measurements are paramount for a precise fit. Using a measuring tape, meticulously measure the rake’s dimensions, particularly the length and width of the tines and the overall rake head. Corresponding measurements of the bucket’s structure, including the available attachment points and the space around them, are equally important. Transfer these measurements to the rake and bucket using a marking pen or a similar tool.

This ensures alignment during the actual modification process.

Importance of Accurate Measurements

Inaccurate measurements can lead to a poorly fitting attachment. This can result in instability, hindering the rake’s operation and potentially causing damage to either the rake or the bucket. A precise fit is essential for ensuring the rake’s smooth operation and longevity. Examples of issues caused by inaccurate measurements include: the rake not staying in place during use, leading to slippage or damage; the rake’s tines potentially scraping against the bucket’s sides, wearing down the metal; and the rake’s excessive movement, reducing the effectiveness of the work.

Attachment Points

The selection and design of attachment points are critical for a secure and functional adaptation. Robust, reliable attachments are needed to prevent slippage and ensure the rake stays in place during operation. Consider using sturdy bolts, brackets, or other suitable fasteners. These attachments should be positioned strategically to distribute the load evenly across the bucket and the rake, preventing strain on the attachment points.

For example, a simple bolt-and-nut system might be suitable for a light-duty rake, while a more complex design might be necessary for a heavier-duty rake.

Adaptation Methods and Their Considerations

| Adaptation Method | Advantages | Disadvantages |

|---|---|---|

| Using existing bucket mounts | Simplicity, speed, potential for minimal modification | Limited adjustment possibilities, potential for strain on existing mounts |

| Modifying existing bucket mounts | Adaptability to varying rake sizes and designs | Requires more time and effort, potentially compromising the bucket’s structural integrity if not carefully done |

| Creating new mounts | Maximum customization and adaptability to specific rake and bucket combinations | Time-consuming and potentially complex, requires specialized tools and skills |

Careful consideration of the advantages and disadvantages of each method is vital for choosing the best approach for a specific application.

Practical Implementation of the Modification

Getting your 3-point rake ready for bucket attachment requires careful steps and attention to detail. Skipping any part of the process could lead to a poorly secured and potentially dangerous setup. This section will guide you through the practical implementation, emphasizing safety and a robust connection.The process involves disassembling parts of the rake and attaching them to the bucket using appropriate fasteners.

Precise measurements and proper alignment are crucial for a stable and functional setup. A well-executed modification ensures the rake operates efficiently and safely on your equipment.

Disassembly and Preparation of the Rake

Thorough preparation is key to a successful modification. Begin by carefully removing any components that will interfere with the attachment process. This may involve detaching existing hardware or removing sections of the rake’s frame. Note the placement and function of all parts as you take them apart. A diagram or photos taken during this stage can prove invaluable during reassembly.

Attachment Point Identification on the Bucket

Selecting the optimal attachment points on the bucket is critical for a stable and balanced rake assembly. Consider the rake’s weight distribution and the bucket’s structural integrity when choosing mounting locations. Ensure the chosen points can effectively support the rake’s weight and allow for smooth operation.

Securing the Rake to the Bucket

A secure attachment is paramount for safe operation. Various fasteners, including bolts, rivets, or welding, can be employed, depending on the rake and bucket materials. Selecting the appropriate fastener type is crucial to prevent loosening or breakage during operation. Consider the load the fasteners will need to bear when making your selection.

Fastener Selection and Application

Appropriate fasteners are essential for a secure connection. Bolts are generally preferred for their versatility and adjustability. Rivets provide a permanent connection, while welding offers the strongest bond but requires specialized equipment and skills. Carefully choose the fastener type based on the materials involved and the expected load. Ensure the chosen fasteners have appropriate threads or dimensions to match the holes on the rake and bucket.

Use washers and locknuts to prevent loosening during operation. Consult the manufacturer’s specifications for any recommended fastener types.

Ensuring a Secure and Stable Connection

Achieving a stable connection requires meticulous attention to detail. Proper alignment between the rake and bucket is crucial for efficient operation and prevents stress on the attachment points. Use shims or spacers if needed to ensure proper alignment. Double-check all connections and tighten all fasteners securely after the initial assembly. Periodic checks and adjustments should be done during operation to ensure the stability of the assembly.

Test the attachment with light loads before applying heavier loads. The final test should involve operating the modified rake under typical conditions to verify functionality and stability.

Safety Precautions During Modification, How to adapt 3 pt lawn rake to my bucket

Safety is paramount during any modification process. Always wear appropriate safety gear, including eye protection, gloves, and hearing protection, when working with tools. Work in a well-lit area and ensure a clear workspace. Keep children and pets away from the work area. Properly handle and store all tools and materials to prevent accidents.

Ensure that any tools you use are in good working order and are appropriate for the task. Be aware of potential hazards during the modification process. Check for any sharp edges or protruding parts.

Testing and Refinement of the Adaptation

Putting your modified 3-point rake-bucket system through its paces is crucial for ensuring smooth and efficient operation. Thorough testing will reveal potential weaknesses and allow you to make necessary adjustments before the system is put to work in a real-world scenario. This phase involves both rigorous evaluation and targeted problem-solving.

Testing Procedure

A systematic testing procedure is essential for identifying and addressing potential issues early in the process. The procedure should include multiple tests to cover various operational conditions. Start with low-load tests and gradually increase the load to simulate real-world usage. Document each test thoroughly, noting any observed behaviors, performance metrics, and any deviations from expectations.

Evaluating Stability and Functionality

Evaluating stability and functionality involves assessing the system’s response to different forces and loads. Stability is paramount; any instability can lead to damage or injury. Functionality refers to the rake’s ability to effectively perform its intended task. These evaluations should be performed under various conditions to ensure reliability. For instance, consider testing with different rake angles, uneven terrain, and varying load weights.

The goal is to determine the system’s limits and capabilities.

Identifying and Resolving Issues

This phase involves proactively seeking and fixing any shortcomings. Regularly inspect the attachment points for any signs of wear or stress. Look for any gaps, misalignments, or excessive play in the system. Detailed documentation of observed issues is vital for accurate problem diagnosis. Using a systematic approach to identify and address issues will save time and resources.

Examples of Potential Issues

Potential issues include loose or broken bolts, misaligned components, and inadequate support structures. For example, if the rake attachment points are not properly secured, the rake might shift during operation, leading to instability. Another example involves insufficient bracing, which can cause the entire system to flex or buckle under load.

Adjusting for Optimal Performance

Adjustments are necessary to optimize the performance of the modified rake-bucket combination. Ensure all fasteners are tight and secure. Check for proper alignment of the rake with the bucket. Any misalignment can lead to uneven distribution of forces, potentially causing damage or reduced efficiency. Pay attention to the rake’s angle relative to the ground; this can impact the rake’s effectiveness and stability.

For example, adjusting the rake angle can optimize the amount of material collected or moved.

Maintaining and Troubleshooting the Adapted System

Maintaining your adapted 3-point lawn rake and bucket system is crucial for its longevity and optimal performance. Regular upkeep prevents unexpected breakdowns and ensures the system remains efficient for years to come. This section details the necessary steps for proper maintenance, identifies potential issues, and provides troubleshooting guidance.Regular maintenance, including lubrication and inspection of critical components, is paramount to maintaining the system’s structural integrity and performance.

This proactive approach significantly reduces the likelihood of costly repairs and downtime.

Maintenance Procedures

Proper maintenance involves several key steps. Thorough cleaning and lubrication are vital to prevent rust and friction, while regular inspections help catch potential problems early.

- Cleaning: Remove debris and dirt from all moving parts and attachment points. Use a brush or compressed air to dislodge stubborn particles. A mild detergent solution, followed by thorough rinsing, can effectively remove caked-on grime. Thorough cleaning helps prevent rust formation and ensures smooth operation.

- Lubrication: Apply a suitable lubricant, such as grease or oil, to pivot points, hinges, and other moving components. This reduces friction, extending the life of the system and enhancing its smoothness. Proper lubrication prevents unnecessary wear and tear. Use a quality lubricant appropriate for the metal type to avoid damage.

- Inspection: Regularly inspect all components for signs of wear and tear, such as cracks, loose fasteners, or bent parts. Visual inspections should focus on identifying any damage to the rake tines, the bucket’s frame, and the attachment points. Address any issues promptly to avoid escalating problems.

Troubleshooting Common Problems

Potential issues may arise during operation, requiring prompt diagnosis and resolution.

- Sticking or Binding: If the rake or bucket assembly experiences sticking or binding, carefully inspect all pivot points for obstructions or excessive wear. Lubrication is often the solution. If lubrication doesn’t resolve the problem, check for any bent or damaged components. If these are present, a repair or replacement may be necessary.

- Loose Fasteners: Loose fasteners can lead to instability and potential damage. Regularly tighten all bolts and screws to ensure secure attachment. This precaution helps to prevent misalignment and ensure the integrity of the assembly.

- Rake Tine Damage: Damaged rake tines can compromise the rake’s effectiveness. Inspect the tines for bending, breakage, or dulling. Replace damaged tines with new ones, ensuring compatibility with the rake design. Replacement ensures optimal functionality and safety.

Wear and Tear Points and Prevention

Identifying potential wear points allows for proactive maintenance.

- Pivot Points: Pivot points are particularly susceptible to wear due to constant movement. Regular lubrication is critical to minimize friction and prolong the lifespan of these components. Regular lubrication and inspection are crucial to preventing damage and prolonging the life of the pivot points.

- Attachment Points: The attachment points between the rake and the bucket are crucial for secure operation. Inspect fasteners regularly for tightness and any signs of damage. Tightening fasteners prevents loosening and potential damage. Regular inspection ensures the structural integrity of the attachment points.

Maintenance Tips for Durability

Following these guidelines ensures long-term durability and efficient performance.

- Store Properly: Store the adapted system in a dry, sheltered location to prevent rust formation and damage from the elements. Proper storage helps prevent corrosion and extends the lifespan of the equipment.

- Record Maintenance: Keep a log of maintenance activities, including dates, procedures, and any issues encountered. This record-keeping helps track the system’s history and aids in future troubleshooting.

Tools Required

The following tools are commonly used for maintenance.

| Tool | Description |

|---|---|

| Screwdrivers (various types) | For tightening and loosening fasteners |

| Wrench Set | For tightening and loosening nuts and bolts |

| Lubricant (grease, oil) | For lubricating moving parts |

| Cleaning Supplies (brushes, rags, compressed air) | For cleaning the system |

Summary

In conclusion, adapting your 3-point lawn rake to a bucket is a rewarding project. This comprehensive guide has provided you with the knowledge and steps to achieve a custom solution tailored to your needs. From selecting compatible equipment to the meticulous implementation process, we’ve covered every crucial detail. With careful planning, precise execution, and proper maintenance, your adapted system will become an indispensable tool for your yard work, making outdoor tasks faster, easier, and more efficient.

Essential Questionnaire

What types of buckets are suitable for this adaptation?

A variety of buckets can be used, including steel, aluminum, or even plastic, depending on the rake model and desired durability. Consider the weight capacity and material compatibility when choosing a bucket.

What safety precautions should I take during the modification process?

Always wear safety glasses and gloves. Ensure the attachment is secure and stable to prevent accidental detachment or injury. Work in a well-lit area.

What are some common problems that may arise during the testing phase?

Potential issues include instability, inadequate attachment, or misalignment. Careful inspection and adjustments will resolve these issues.

What tools are necessary for maintenance?

Basic tools like screwdrivers, wrenches, and a hammer might be needed, depending on the chosen fasteners. Consult your specific adaptation instructions for detailed tools.